The Impact of Technological Innovations on Electronics Manufacturing

Today’s fast-paced world of electronics manufacturing is being reshaped by technological innovations from automation to advanced data analytics. These technologies are also transforming how businesses operate and compete, driving change across all sectors. This article explores the profound industry impact of these advancements and the potential future of electronics manufacturing.

Emerging Technologies

Emerging technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and automation are transforming electronics manufacturing in ways previously unimaginable. Together, these technologies create a robust foundation for a smarter, more efficient manufacturing sector, paving the way for future innovations.

- AI in Electronics Manufacturing: Artificial Intelligence is pivotal in streamlining manufacturing workflows, optimizing supply chains, and minimizing human error. Through predictive maintenance and data-driven insights AI helps prevent costly downtimes and optimizes equipment operation, leading to improved productivity and reduced wastage.

- IoT’s Role: The Internet of Things (IoT) connects various devices and machinery, enabling seamless data exchange and real-time monitoring across the manufacturing floor. This connectivity allows manufacturers to monitor equipment status, track components and improve transparency across the production line, enhancing operational efficiency.

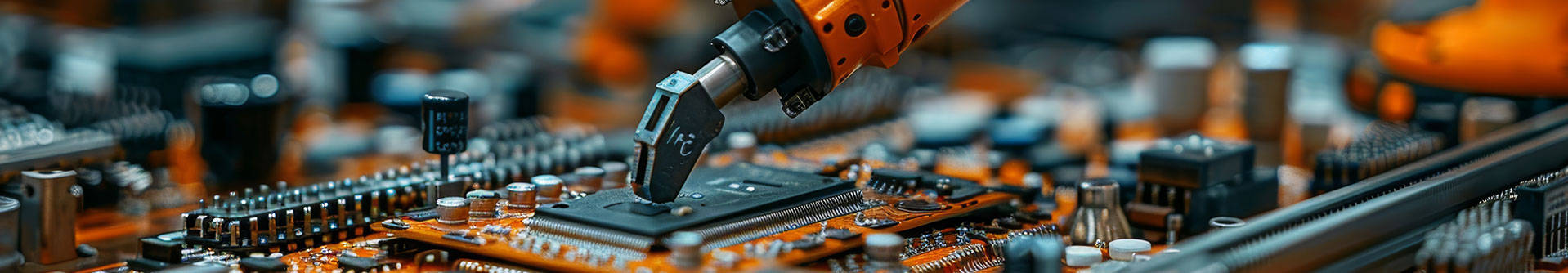

- Automation: Automation has redefined the landscape of electronics manufacturing, from assembly to quality control. Automated processes reduce the reliance on manual labor, improve precision in manufacturing and accelerate production speeds, leading to a more agile and responsive manufacturing environment.

The Kitting Experts

From complete BOM to consigned and turnkey kits, we are the premier shop, with more than 60 years combined knowledge in the electronics components field.

DETAILSFuture Prospects

The future of electronics manufacturing is full of exciting possibilities. Innovations and trends such as flexible electronics, miniaturization and advances in PCB manufacturing will continue to shape the next generation of electronic components.

- Future of Electronics Manufacturing: In the near future electronics manufacturing will be defined by further integration of smart technologies and an increased focus on sustainability. Advanced materials and energy-efficient designs will become central to product development, as the industry strives to minimize its environmental footprint.

- Innovative Trends: Key trends, such as additive manufacturing and 3D printing, will continue to gain traction, enabling manufacturers to produce complex components with unprecedented precision. Similarly, flexible electronics will allow for the development of new, versatile devices that can fit into various applications, expanding the possibilities for consumer and industrial electronics.

- Future of PCB Manufacturing: Automation and AI-driven processes are expected to optimize the design and assembly of printed circuit boards. With innovations like AI-enhanced design software and automated quality control systems, PCB manufacturing will become faster, more efficient and capable of meeting the growing demand for complex, high-quality electronics.

The convergence of these trends will undoubtedly transform electronics manufacturing into a more dynamic and future-ready industry. The integration of AI, IoT, and automation into core manufacturing processes ensures that the sector remains competitive, adaptable and ready to meet the challenges of tomorrow.

Materials Management

We store your materials in a climate-controlled and ESD stockroom with a segregated customer inventory area. No extra or hidden fees for handling or BOM changes.

DETAILS