Benefits of Using Automated Equipment in Electronics Manufacturing

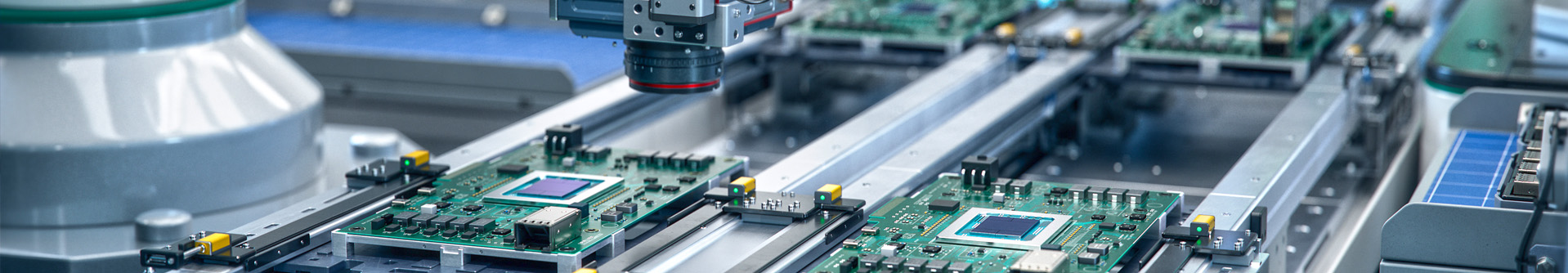

The use of automated equipment in electronics manufacturing has become increasingly prevalent in today’s rapidly evolving industrial landscape. The array of benefits it offers continues to drive this shift towards automation, including enhanced precision, substantial cost savings and overall improvements in production efficiency. As companies strive to stay competitive, the integration of automated machinery in the manufacturing process has proven to be a crucial factor in achieving high-quality outcomes while reducing operational costs.

Increased Precision and Accuracy

One of the primary advantages of incorporating automated equipment in electronics manufacturing is the remarkable increase in precision and accuracy. Automated machinery, designed to execute tasks with minimal human intervention, ensures that each component is assembled with exacting detail. This level of precision is critical in electronics manufacturing, where the slightest deviation can lead to defective products or system failures.

Automated optical inspection (AOI) systems are a prime example of how automation boosts accuracy. These systems use high-resolution cameras and advanced algorithms to inspect electronic components and assemblies, identifying defects that might be missed by human inspectors. By leveraging automated machinery, manufacturers can consistently produce products that meet stringent quality standards, minimizing errors and reducing the likelihood of costly recalls or rework.

The Kitting Experts

From complete BOM to consigned and turnkey kits, we are the premier shop, with more than 60 years combined knowledge in the electronics components field.

DETAILSCost Savings and Efficiency

Automation in electronics manufacturing is not only about improving precision; it also brings valuable cost savings and a high degree of production efficiency. Automated equipment can operate continuously, considerably lowering downtime and allowing for faster production cycles. This leads to gains in throughput and the ability to meet higher demand without compromising quality.

The cost savings associated with automation are multifaceted. First, automation lessens labor costs by eliminating the need for manual intervention in repetitive tasks. Second, the greater efficiency of automated systems leads to a drop in energy consumption and material waste. Finally, the precision offered by automated machinery makes errors less likely to occur which results in fewer defective products and decreased overall production costs.

In conclusion, the adoption of automated equipment in electronics manufacturing presents clear benefits, from bolstering precision to hefty cost savings and added production efficiency. As the industry continues to evolve, companies that embrace automation will be better positioned to deliver high-quality products at competitive prices, safeguarding their long-term success in the marketplace.

Materials Management

We store your materials in a climate-controlled and ESD stockroom with a segregated customer inventory area. No extra or hidden fees for handling or BOM changes.

DETAILS